Weaving Success: How Fiberglass Cloth Revolutionizes Composite Production

Discover the Benefits of Fiberglass Fabric

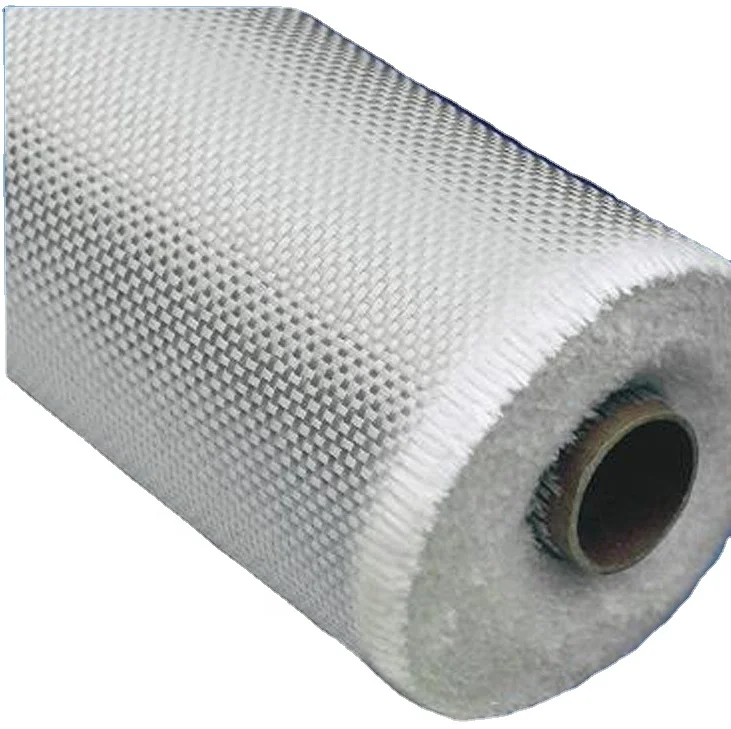

Fiberglass cloth is one of the most notable materials that revolutionized the composite products creating industry. Its exclusive qualities and functionality render it diverse for various industries. We will take a closer look at fiberglass cloth to discover all of the ways in which it can improve your projects.

Benefits of Fiberglass Cloth

There are many benefits to choosing fiberglass cloth over other materials. It is not only highly resistant to chemical wear and corrosion but also it is super strong and light. In addition fiberglass cloth can withstand extreme temperature deviation and non-conductible nature makes it a perfect choice to the applications in electrical field. Because of its formable characteristics, it conforms to any shape or size which facilitates an efficient manufacturing procedure.

Fiberglass Cloth Development

Fiberglass cloth has been around for a while, but it is important to note that there have also been many changes in fiberglass technology as the needs of composite production advanced. Advances in the material now make composites stronger, more water-, and chemical-resistant than ever as well aesthetically superior. These developments have fostered a rise in the application of glass fiber fabrics through different sectors, testifying its surging significance within composite fabric manufacturing.

Safety Considerations

In composite production, fiberglass cloth is very commonly used and naturally safety should be of utmost importance. Skin exposure to the small fibres of which woven fiberglass is made up can result in skin irritation so wear appropriate protective clothing. Gloves, goggles or a mask must be worn to avoid any risks. By doing so, you will not only ensure a reliable and efficient production process but also guarantee the safety of workers in your shop.

Properties of fabric carbon fiber

It is used in a wide variety of products, everything from boats and cars to aircrafts or sports equipment. It is also used for roofing and cladding applications in the architectural segment. Fiberglass cloth can be molded and then used to form high-quality composites that are durable but still look extremely smooth.

Utilizing Fiberglass Cloth

Working with fabric fiberglass cloth is a somewhat easy process. Step 1: Sand the surface or mold to rough it up for a better bond with the fiberglass cloth. Then lay the fabric on top of substrate, and saturate them with resin. The resin curing process solidifies and stiffens the wetted fabric to create a lightweight, long-lasting composite material. And, because of this, it can be a very cost-effective choice as well for your composite application.

Focus on Service and Quality

The fiber glass mat you choose here is an important one because when it comes to your composite endeavors, a vendor that provides excellent service and quality cannot be emphasized enough. Quality manufacturers not only produce top-of-the-range products, but also offer incredible technical support s consultation and training as well. Using a premium manufactured trailer that prioritizes service and quality means it suits your production needs but is as reliable as third-party data available.

As such, fiberglass cloth serves as one of the most versatile and valuable composite creation materials. These attributes, along with its numerous benefits like continuous innovation in the R&D of products, strict safety protocols and user-friendliness coupled by an excellent service culture enforced for maintaining product quality have all made it one of first choices to go ahead while making fine composite products. To experience the full benefits of fiberglass cloth and work together with great manufacturers for your composite projects going to succeed.