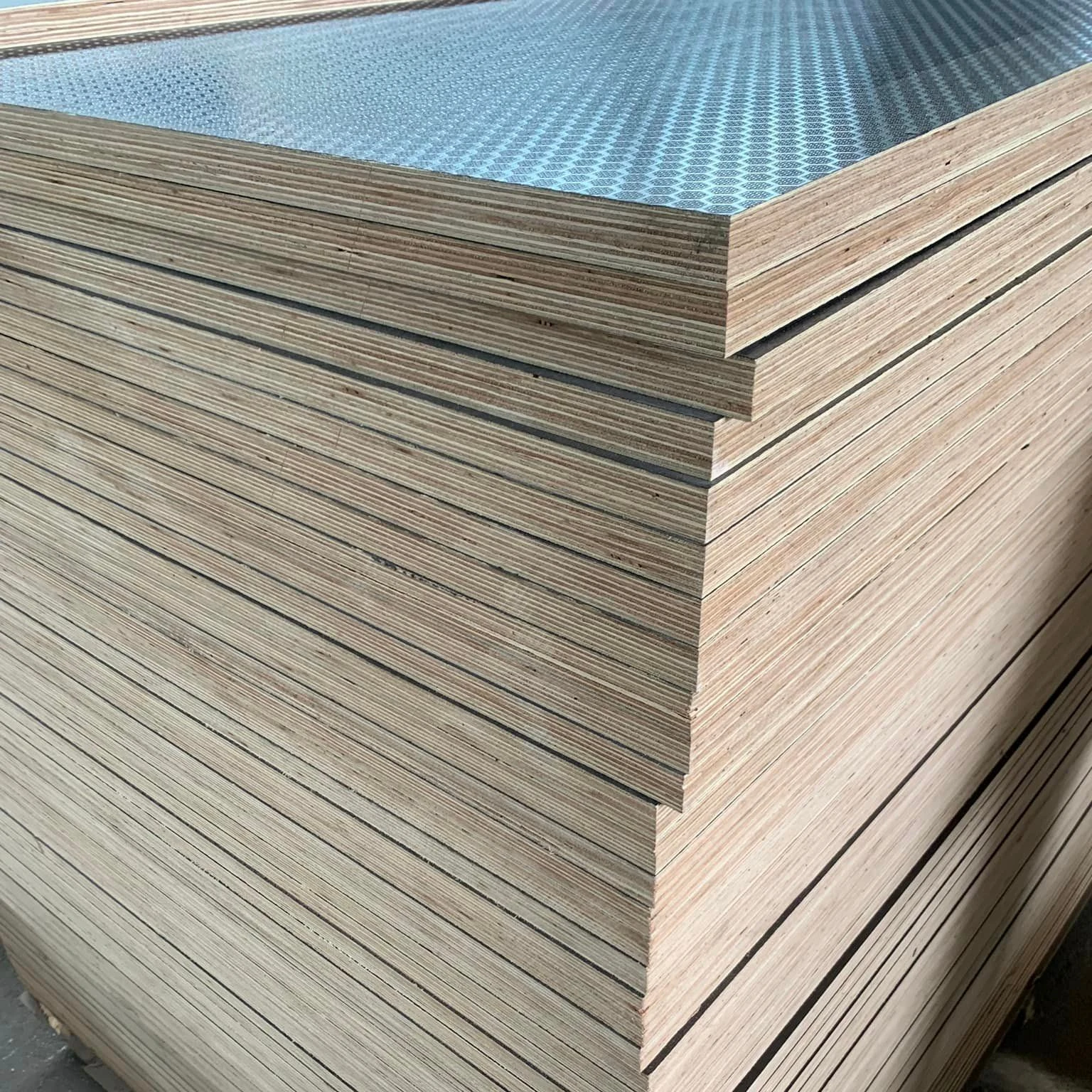

Film Faced Plywood: Resisting Moisture and Abrasion in Concrete Forms

Why Film Faced Plywood is Well-Suited for Your Construction Work!

Looking for a suitable material that you must use in constructing projects? A significant role can be played by film faced plywood in this scenario. The unbeatable building material comes with a variety of benefits, turning it into the go-to option for all your construction needs.

Its benefits: I would like to remind that this information is specific to the subject of study under Film Faced Plywood

Film faced plywood is a type particularly made use of for making concrete structures, guaranteeing that your very own productions are light along with long lasting. Its specialized functions make it the ideal choice for standing up to building websites tough conditions. Here are some of the advantages it offers:

Resistance to Moisture: Film faced plywood is similarly resistant to moisture and it will not bend out of shape or swell. This allows you to utilize them in wet conditions with no loss of stability on your buildings.

Scratch and Stainability: The material is scratch-proof, overshadowing most natural stones thus fit for areas of high usage.

Resistance: Very sturdy especially for a site of construction. Designed For Forever: Providing durable and ever-lasting construction solutions.

Easy to use: Film faced plywood is very easy in terms of utilization. Lends itself to heavy modifications: Cuts and shapes precisely the way you want it. It is also lighter weight, so easier to deliver and handle at the job site.

Safe Click Plywood Varieties

The advancement of the film faced plywood today provides more benefits in terms of its sustainably, dependability and operable traits such that it can withstand longer years accordingly. Thanks to its advantageous properties film faced plywood is now increasingly becoming the most preferred building material by construction professionals.

Prioritizing Safety

Sr: Safety first while using film faced plywood. Construction Site Safety Protocols And Guidelines To Avoid Incidents Or Injuries When using material, don whatever safety equipment is recommended and follow the manufacturer guidelines.

Film Faced Plywood Utilization Guide

The use of film faced plywood works in the most convenient way. It follows some basic steps:

Step 2: Measuring and CuttingMeasuring & cutting the plywood to size

Sealing the Deal: Attach screws or nails through the plywood to anchor it firmly in place.

Concrete Form Plywood for pouring Concrete

Remove After Curing: Once the cement has hardened, take off your plywood from the form.

Quality and service are key here.

Film faced plywood has an excellent selection of reliable manufacturers when purchasing this kind of material. You must choose a supplier that is reputed in the industry of manufacturing products with sustainability and high quality. And make sure to choose a layout & design service that provides great customer support if you need assistance with your plans and construction.

Applications in Construction

As can be seen, film faced plywood is commonly used in many construction projects.

Bridges

Parking Structures

Highways

Tunnels

Industrial Plants

Residential Buildings

Commercial Buildings

Concluding Thoughts

Commercial plywood Products is the best choice for structures that require high moisture and abrasion resistance. Additionally,its unique characteristics are durable and easy to work with this makes it a perfect material for all sizes of projects. So if you need to use some construction materials consider film faced plywood — it worths trying!